IIoT for Maintenance Departments

A customer places an order for a custom-designed car. Even before the order process is complete, production is already in progress. Intelligent, autonomous machines monitor the manufacturing process, communicate in real time, and coordinate the entire production process autonomously. Does this sound like a vision of the future? Not at all. Welcome to the Industrial Internet of Things (IIoT)!

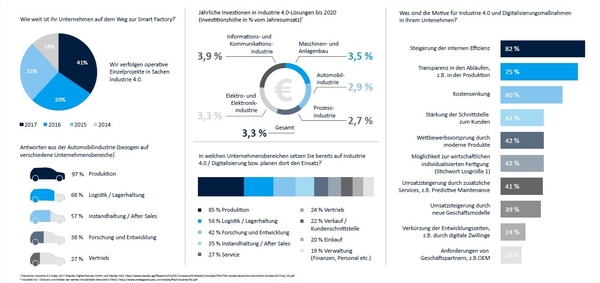

State of the Industrial Internet of Things

The full potential of this emerging development is far from being realized. But it's clear that the Fourth Industrial Revolution, driven by today's information and communications technologies, is well underway. Advanced IT infrastructures have enabled an unprecedented interconnection of production facilities, components and devices. Powerful sensors can now collect and share real-time data, making production processes more agile and efficient.

This transformative power isn't limited to manufacturing processes. The IIoT is changing the way businesses and stakeholders interact. Employees, customers, remote workers, and partners now have direct access to the production system, which presents a significant challenge because disparate data from multiple sources must be harmonized for effective communication. Data management plays a critical role in achieving this interoperability.

Importance of the Industrial Internet of Things for Maintenance Personnel

The IIoT introduces new tasks to existing roles and provides companies with tools to enhance business development, optimize processes, and improve efficiency. Maintenance is a prime example. Downtime due to malfunctioning equipment is a nightmare for maintenance technicians, but with elements of a production line capable of self-diagnosing maintenance needs and identifying error patterns through massive data sets, predictive maintenance becomes a reality. This is revolutionizing the work environment and job descriptions of maintenance personnel. Let's take a closer look at these and other IIoT trends.

IIoT Solutions for Maintenance

Intelligent maintenance transforms traditional corrective practices into predictive ones. Identifying indicators of failure requires the extraction, collection, and analysis of multiple types of data.

Implementing this transformation challenges existing IT infrastructures and introduces potential sources of error. Predictive actions can only be accurate with reliable data.

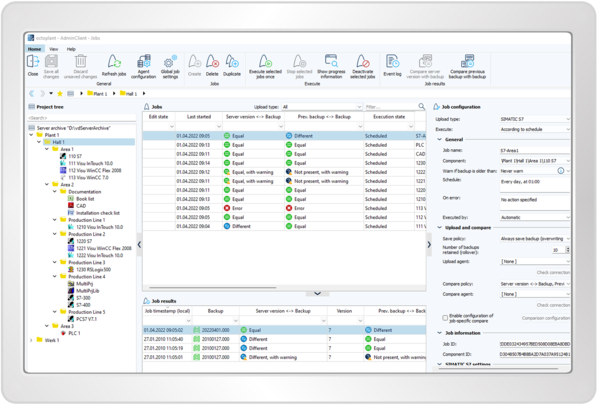

What if data is corrupt or missing? Quickly detecting and correcting such instances while minimizing data loss requires robust documentation, version control, and automated backups-a task for modern data management.

Discover how octoplant's advanced IIoT solutions can seamlessly transform your maintenance approach from corrective to predictive. By efficiently extracting, collecting and analyzing multiple types of data, OctoPlant enables you to identify indicators of failure with unparalleled accuracy.