One Small Change Is a Big Deal on the Production Line

Keep track of it all with octoplant, version control software for food and beverage manufacturers that automates the backup process, provides complete change history, and validates compliance with quality standards.

Automated production works until it does not

In the food and beverage industry, there are many regulations that must be adhered to for both the products and the production processes that must meet the highest quality standards. FDA standards and regulations are critical. With octoplant, a version control software for food and beverage manufacturers, you can keep track. The software automates the backup process, provides a complete change history, and ensures compliance with quality standards.

Complete Traceability

octoplant's comprehensive change history provides accurate traceability of all changes in the production process, detailing who, what, when, and where.

Adhering to Conformity

octoplant provides effective verification of compliance with quality standards, including FDA regulations such as 21 CRF 11, to strengthen quality assurance and ensure the highest product quality.

Standardized Logging

octoplant provides seamless logging at the touch of a button. Standardized documentation in the audit trail saves time and allows efficient tracking of project details.

Thanks to the solution from AUVESY-MDT, we are able to rapidly localise errors and get the plant back up and running again. The wonderful thing about the software is that fact that you know when exactly a particular change was made, who made it, and why it was made.

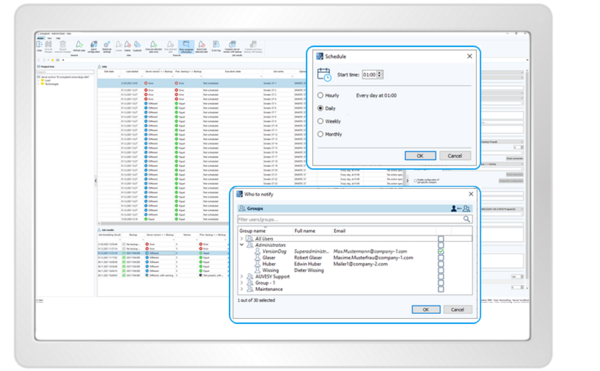

Standardized backup strategy

With octoplant, you can implement a standardized backup strategy for networked and non-networked systems. Machines and systems can be monitored manually or scheduled based on rules, and program states can be compared.

- Ensure maximum data protection with regular, automated backups

- Save time by eliminating the need for a manual change journal

- Easily recover from data loss or unintentional changes

- Minimize downtime, lost production, and product recalls

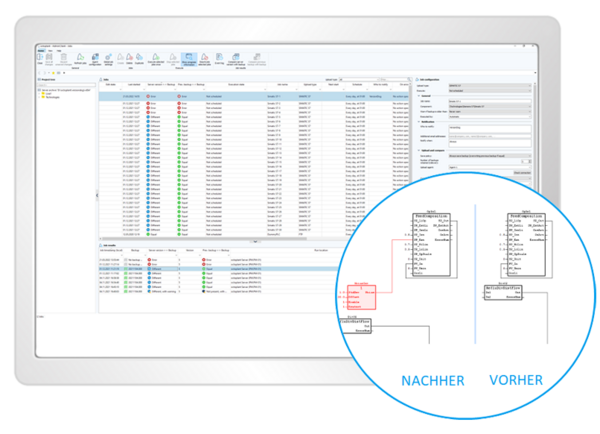

Clear analysis of version differences

octoplant simplifies the comparison of various versions and statuses through clear change detection and analysis. This can be done graphically, in tabular form, or textually.

- Constant availability and use of the latest released version

- Security and control in collaboration with suppliers

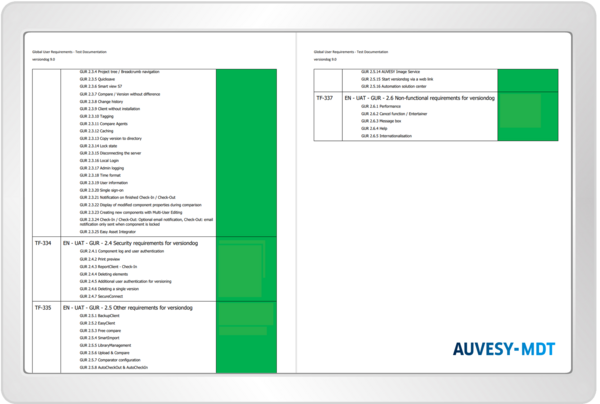

Audit trails at the touch of a button

octoplant provides answers to typical process documentation questions (what, why, who, when, where) in a standardized and efficient manner. The high level of data transparency and traceability is realized through audit trails at the push of a button in compliance with applicable IT laws.

- Document even the smallest project differences

- Audit trails at the touch of a button

- Eliminate paper trails

Get a 360-Degree View of Your Production Environment

octoplant supports more devices than anyone else in the industry, including PLCs (e.g. TIA Portal), SCADA systems, HMIs, and robots from different manufacturers. This hepls you better analyze the shop floor, isolate errors, and fix any problems. See for yourself!

NIS2’s new security regulations are forcing industry and suppliers to act

Discover the impact of the EU NIS2 Directive on manufacturing companies! With penalties of up to €10 million or 2% of global turnover, stricter cybersecurity requirements are a reality for industries such as beverages, food, and more. Our free guide offers concrete solutions to ensure compliance and minimize cyber threats.

Download the free whitepaper now!