Minimized Downtimes Secure Global Just-in-time Production at thyssenkrupp Presta

One of the world's leading automotive suppliers relies on octoplant version control software to ensure business continuity.

The use case at a glance:

- 24 production plants worldwide, including in Europe, the USA and China

- Production of steering systems for more than 30 million vehicles per year

- Securing the just-in-time supply chain with octoplant: Disaster recovery within minutes

The Initial Situation

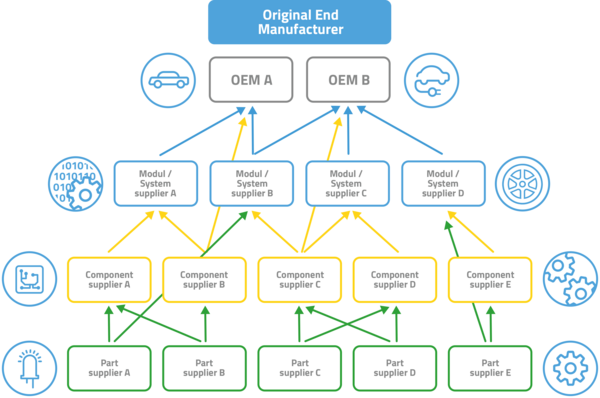

thyssenkrupp Presta is one of the most successful suppliers to the automotive industry: Components from the OEM are installed in one of four cars worldwide. At its 24 production sites worldwide, the company relies on a wide range of automation technologies to manufacture its steering systems. To avoid long downtimes, this complex system must function seamlessly. In the automotive industry, which is characterized by lean manufacturing and just-in-time supply chains, any production downtime can pose a significant business risk. Having backup technology in place is critical to quickly resume production after an outage and avoid severe contractual penalties.

octoplant is part of our recovery strategy for our industrial production control systems. In case of an emergency, we can restore entire production lines within minutes and maintain the supply chain.

The Solution

This is precisely why thyssenkrupp Presta AG relies on the octoplant version control software. It enables and simplifies modular asset and device management and secures the entire production chain with automated backups.

With octoplant, restarts that used to take several hours can now be realised in just a few minutes. The software continuously monitors and documents all changes. This enables quick tracking of unwanted adjustments and replaces manual, site-specific troubleshooting.

The Result

Thanks to octoplant, production lines can be restored in just a few minutes in the event of a malfunction. The early detection of unwanted changes enables the preventive avoidance of many disruptions. thyssenkrupp Presta achieves its just-in-time targets despite the complexity of its production sites and technologies. Supply chains are maintained and high contractual penalties are avoided. This ensures long-term successful cooperation with business partners.

Contact us

Want to learn more about automatic backups, versioning and documentation in automated production?

Contact us